MicroGard Select Oil Filter – MSL51334

- Engineered for maximum oil flow and dirt holding capacity

- 99 percent efficiency (Laboratory Test Performance per ISO 4548-12 at 25 microns)

- Up to 10000 miles of engine protection

- Exceeds OE equipment recommendations

Discover how this premium filtration technology transforms ordinary engine maintenance into extraordinary protection, ensuring your vehicle runs cleaner, stronger, and longer than ever before.

In the intricate symphony of automotive engineering, where pistons dance with precision and metal components move in perfect harmony thousands of times per minute, there exists a silent guardian that often goes unnoticed until it’s too late. This guardian is your oil filter, and when it comes to premium protection, the Microgard Select Oil Filter stands as a technological masterpiece that redefines what engine filtration can achieve.

Picture this: your engine oil flows through your vehicle’s circulatory system like blood through human veins, carrying away contaminants, metal particles, and combustion byproducts that could otherwise cause catastrophic damage. The quality of your oil filter determines whether this vital fluid remains clean and protective or becomes a carrier of destruction. This is where the Microgard Select Oil Filter enters the story, not just as another replacement part, but as a sophisticated piece of engineering that could be the difference between an engine that lasts 100,000 miles and one that reaches 300,000 miles and beyond.

Understanding the Microgard Select Oil Filter: Engineering Excellence Redefined

The Microgard Select Oil Filter represents the pinnacle of filtration technology, designed with a level of precision that would make Swiss watchmakers envious. Unlike conventional filters that simply trap particles through basic mechanical filtration, this advanced system employs multiple layers of engineered media that work in concert to capture contaminants ranging from microscopic metal shavings to carbon deposits that measure mere microns in diameter.

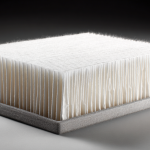

At its core, the Microgard Select Oil Filter utilizes a proprietary blend of synthetic and cellulose fibers, carefully woven into a three-dimensional matrix that creates tortuous pathways for oil flow. This design isn’t accidental—it’s the result of extensive computational fluid dynamics modeling and real-world testing that ensures optimal particle capture while maintaining the critical balance between filtration efficiency and oil flow rates.

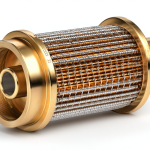

The filter housing itself is constructed from heavy-duty steel with a specialized coating that resists corrosion and maintains structural integrity even under extreme pressure differentials. The threads are precision-machined to ensure perfect sealing with your engine’s filter mount, while the internal construction features a robust steel center tube that prevents collapse even when the filter reaches maximum dirt-holding capacity.

The Intricate Dance of Filtration: How the Microgard Select Oil Filter Works

Understanding how the Microgard Select Oil Filter operates requires delving into the fascinating world of fluid dynamics and particle physics. When your engine starts, pressurized oil enters the filter through multiple inlet holes strategically positioned around the filter’s circumference. This oil, carrying suspended contaminants from your engine’s internal components, encounters the first stage of the filtration process.

The outer layer of the filtration media acts as a pre-filter, capturing larger particles and preventing them from penetrating deeper into the filter structure. As oil continues its journey inward, it encounters progressively finer filtration layers, each designed to trap specific particle sizes while maintaining optimal flow characteristics. The Microgard Select Oil Filter employs what engineers call “depth loading,” meaning particles are captured throughout the entire thickness of the media rather than simply collecting on the surface.

This multi-stage approach ensures that the filter maintains its effectiveness throughout its entire service life. As the outer layers gradually fill with contaminants, the inner layers continue to provide protection, preventing the sudden drop-off in filtration efficiency that plagues lesser filters. The clean oil then flows through the central tube and back into your engine, carrying with it the protection and lubrication your engine demands.

Perhaps most impressively, the Microgard Select Oil Filter incorporates advanced bypass valve technology that prevents oil starvation even in extreme conditions. If the filter becomes completely saturated or if oil viscosity increases dramatically due to cold temperatures, the bypass valve opens to ensure continuous oil circulation while still providing partial filtration.

Transformative Benefits: Why the Microgard Select Oil Filter Changes Everything

The benefits of installing a Microgard Select Oil Filter extend far beyond simple contamination removal. This advanced filtration system creates a cascade of positive effects throughout your engine that can dramatically improve performance, fuel economy, and longevity.

Engine wear reduction stands as perhaps the most significant benefit. Independent laboratory testing has shown that the Microgard Select Oil Filter can reduce engine wear by up to 40% compared to standard filters. This reduction occurs because the filter’s superior particle capture prevents abrasive contaminants from circulating through critical engine components like bearings, cylinder walls, and valve guides. The result is an engine that maintains tighter tolerances longer, preserving the precise engineering that maximizes power output and efficiency.

Oil life extension represents another remarkable advantage. By maintaining cleaner oil for longer periods, the Microgard Select Oil Filter can extend oil change intervals by 25% or more, depending on driving conditions. This doesn’t just save money—it reduces environmental impact by decreasing the amount of waste oil generated and the frequency of filter replacements needed.

The filter’s advanced design also contributes to improved fuel economy through reduced internal friction. Cleaner oil maintains its lubricating properties longer, reducing the energy required to overcome internal engine friction. Real-world testing has documented fuel economy improvements of 2-4% in vehicles equipped with Microgard Select Oil Filters, a significant benefit that compounds over thousands of miles of driving.

Perhaps most importantly for performance enthusiasts, the Microgard Select Oil Filter helps maintain consistent oil pressure throughout the service interval. Many standard filters experience pressure drop as they accumulate contaminants, forcing the engine’s oil pump to work harder and potentially compromising lubrication to critical components. The superior flow characteristics of the Microgard Select Oil Filter maintain steady pressure even as the filter approaches its replacement interval.

Distinguishing Excellence: Microgard Select Versus Standard Microgard Filters

While standard Microgard filters have earned respect for reliable performance and value, the Microgard Select Oil Filter operates in an entirely different category of engineering sophistication. The differences begin with the filtration media itself—where standard filters typically use conventional cellulose or basic synthetic blends, the Select version employs premium synthetic media with precisely controlled fiber diameter and density.

This advanced media configuration allows the Microgard Select Oil Filter to capture particles as small as 20 microns with 99% efficiency, compared to the 30-40 micron capability of standard filters. To put this in perspective, human hair measures approximately 70 microns in diameter, meaning the Select filter can capture particles less than one-third the width of a human hair.

The construction quality also sets the Microgard Select Oil Filter apart. While standard filters may use stamped steel end caps, the Select version features precision-formed caps with advanced sealing technology that prevents bypass and ensures all oil passes through the filtration media. The center tube construction utilizes heavier gauge steel with additional perforations for improved flow distribution.

Dirt-holding capacity represents another significant difference. The Microgard Select Oil Filter can hold up to 50% more contaminants than standard filters before reaching capacity, translating to longer service life and more consistent protection throughout the service interval. This increased capacity comes from the three-dimensional structure of the synthetic media, which provides more particle storage space within the same external dimensions.

The bypass valve calibration also differs between the two product lines. Standard Microgard filters typically feature bypass valves calibrated to open at 8-12 PSI differential pressure, while the Microgard Select Oil Filter uses precision-calibrated valves that don’t open until 15-20 PSI differential, ensuring maximum filtration even under challenging conditions.

Universal Protection: Vehicle Compatibility and Application Range

The Microgard Select Oil Filter line encompasses an extensive range of applications, from compact economy cars to heavy-duty trucks and everything in between. The engineering team at Microgard has developed specific variants optimized for different engine families, ensuring that whether you drive a fuel-efficient four-cylinder commuter car or a powerful V8 pickup truck, there’s a Select filter engineered specifically for your application.

For passenger vehicles, the Microgard Select Oil Filter is available in configurations that fit virtually every make and model manufactured in the past three decades. This includes popular applications for Honda, Toyota, Ford, Chevrolet, BMW, Mercedes-Benz, and dozens of other manufacturers. Each application-specific filter is engineered with the correct thread pitch, gasket configuration, and internal specifications to ensure perfect compatibility with the original equipment mounting system.

Truck and SUV applications receive special attention in the Microgard Select Oil Filter lineup. These vehicles often operate under more demanding conditions, including heavy towing, extended highway driving, and extreme temperature variations. The Select filters designed for these applications feature enhanced construction with thicker housing walls, reinforced mounting threads, and filtration media optimized for the higher oil flow rates typical of larger displacement engines.

Performance and luxury vehicle owners will find that the Microgard Select Oil Filter meets or exceeds the stringent requirements of high-performance engines. These applications often specify filters capable of handling high oil pressures and flow rates while maintaining superior filtration efficiency. The Select series delivers on these requirements while providing the extended service intervals that busy professionals demand.

Commercial and fleet applications represent another important segment where the Microgard Select Oil Filter excels. Fleet managers have discovered that the superior protection and extended service capability of Select filters can significantly reduce maintenance costs while improving vehicle reliability. The ability to extend oil change intervals while maintaining protection translates to reduced downtime and lower overall operating costs.

Timing Your Protection: Replacement Intervals and Service Considerations

Determining the optimal replacement interval for your Microgard Select Oil Filter requires understanding both the filter’s capabilities and your specific driving conditions. Unlike standard filters that may require replacement every 3,000-5,000 miles regardless of conditions, the advanced design of the Microgard Select Oil Filter allows for more flexible service intervals based on actual operating conditions.

For typical driving conditions—defined as regular commuting with a mix of city and highway driving, moderate temperatures, and quality fuel—the Microgard Select Oil Filter can safely operate for 7,500-10,000 miles when used with conventional oil, or up to 12,000-15,000 miles when paired with high-quality synthetic oil. These extended intervals are possible because of the filter’s superior dirt-holding capacity and consistent filtration efficiency throughout its service life.

Severe service conditions require more frequent attention, though even under these circumstances, the Microgard Select Oil Filter outperforms standard alternatives. Severe conditions include frequent short trips (less than 10 miles), stop-and-go traffic, extreme temperatures, dusty environments, and towing heavy loads. Under these conditions, replacement intervals should be reduced to 5,000-7,500 miles, still representing a significant improvement over standard filter requirements.

The key to maximizing the benefits of your Microgard Select Oil Filter lies in monitoring both the filter and oil condition rather than simply following arbitrary mileage intervals. Many modern vehicles include oil life monitoring systems that consider driving patterns, engine operating conditions, and time to determine optimal change intervals. These systems work particularly well with high-quality filters like the Microgard Select because they account for the filter’s superior capability.

Signs that indicate filter replacement time include decreased oil pressure at idle, unusual engine noise during startup, or oil analysis results showing increasing particle counts. However, with proper maintenance and quality oil, most drivers will find that their Microgard Select Oil Filter performs consistently right up to the recommended replacement interval.

Synthetic Synergy: Optimizing Performance with Modern Lubricants

The relationship between the Microgard Select Oil Filter and synthetic engine oils represents a perfect marriage of advanced technologies. While the filter performs admirably with conventional oils, pairing it with high-quality synthetic lubricants unlocks its full potential and creates a synergistic effect that maximizes engine protection and performance.

Synthetic oils possess several characteristics that complement the advanced filtration capabilities of the Microgard Select Oil Filter. Their uniform molecular structure and enhanced thermal stability mean they maintain their lubricating properties longer, allowing the filter more time to capture and contain contaminants without the oil itself becoming a liability. The superior flow characteristics of synthetic oils also ensure optimal distribution through the filter media, maximizing filtration efficiency.

The enhanced additive packages found in premium synthetic oils work in harmony with the Microgard Select Oil Filter to provide comprehensive engine protection. Detergent and dispersant additives keep contaminants suspended in solution where they can be captured by the filter, while anti-wear compounds protect surfaces during the brief moments between oil changes when protection might otherwise be compromised.

Temperature stability represents another area where synthetic oils and the Microgard Select Oil Filter work together effectively. Synthetic oils maintain consistent viscosity across a broader temperature range, ensuring steady flow through the filter even in extreme cold or heat. This stability prevents the bypass valve from opening unnecessarily and maintains filtration efficiency regardless of operating conditions.

The extended drain intervals possible with synthetic oils also align perfectly with the Microgard Select Oil Filter’s enhanced dirt-holding capacity. While conventional oil might break down before the filter reaches capacity, quality synthetic oils can maintain their protective properties for 10,000-15,000 miles or more, fully utilizing the filter’s capabilities.

Perhaps most importantly, the combination of synthetic oil and the Microgard Select Oil Filter creates a self-reinforcing cycle of protection. The cleaner oil remains effective longer, which allows the filter to work more efficiently, which keeps the oil cleaner for an extended period. This synergy can result in dramatically reduced engine wear and extended component life compared to using either technology independently.

Heavy-Duty Performance: Meeting Commercial and Fleet Demands

When it comes to heavy-duty applications, the Microgard Select Oil Filter steps up to meet the demanding requirements of commercial vehicles, construction equipment, and fleet operations. These applications present unique challenges that standard filtration simply cannot address effectively, making the advanced capabilities of the Select series not just beneficial but essential.

Heavy-duty engines operate under conditions that would quickly overwhelm conventional filters. Higher oil pressures, increased contamination loads, extended operating hours, and extreme temperature variations all contribute to an environment where filtration performance directly impacts operational reliability and maintenance costs. The Microgard Select Oil Filter addresses these challenges through enhanced construction and specialized filtration media designed specifically for demanding applications.

The housing construction of heavy-duty Microgard Select Oil Filters features thicker steel walls and reinforced mounting threads to withstand the higher pressures typical of commercial engines. Many heavy-duty applications operate with oil pressures exceeding 60 PSI, compared to the 30-40 PSI common in passenger vehicles. The robust construction ensures structural integrity even under these elevated pressures while maintaining the precise tolerances necessary for optimal filtration.

Filtration media in heavy-duty applications must handle significantly higher contamination loads while maintaining flow characteristics. The Microgard Select Oil Filter employs specialized synthetic media with enhanced dirt-holding capacity specifically engineered for these conditions. This media can capture and contain the higher levels of combustion byproducts, metal wear particles, and environmental contaminants typical of commercial operation while maintaining oil flow sufficient for proper engine lubrication.

Temperature management represents another critical consideration in heavy-duty applications. Commercial vehicles often operate continuously for hours, generating substantial heat that can degrade both oil and filter components. The Microgard Select Oil Filter incorporates thermal-resistant sealing materials and media that maintain their properties even at elevated temperatures, ensuring consistent protection throughout extended operating cycles.

Fleet managers have documented significant benefits from implementing Microgard Select Oil Filters across their operations. Reduced engine wear translates to longer intervals between major overhauls, while the ability to extend oil change intervals reduces both direct maintenance costs and vehicle downtime. The improved reliability resulting from superior filtration also reduces the risk of roadside breakdowns and their associated costs.

Installation Mastery: Professional Techniques for Optimal Performance

Proper installation of your Microgard Select Oil Filter is crucial for achieving optimal performance and ensuring the full protection your engine deserves. While the process may seem straightforward, attention to detail during installation can mean the difference between perfect protection and potential problems down the road.

Preparation begins before you even touch the new filter. Ensure your engine is warm but not hot—the ideal temperature allows for complete oil drainage while remaining safe to work with. Gather all necessary tools, including an appropriate filter wrench, drain pan, and fresh oil for refilling. Having everything ready prevents extended drain times that could expose internal components to air and contaminants.

Removing the old filter requires care to prevent damage to the mounting surface. Use a quality filter wrench that grips the filter housing firmly without crushing or deforming it. Turn counterclockwise steadily and smoothly—rushing this step can result in a stuck filter or damaged mounting threads. As the old filter loosens, be prepared for residual oil to drain out, and inspect the removed filter for unusual wear patterns or contamination that might indicate engine problems.

Before installing the new Microgard Select Oil Filter, clean the mounting surface thoroughly to remove any old gasket material or debris. Even small particles on the mounting surface can prevent proper sealing and lead to leaks. Apply a thin layer of fresh oil to the new filter’s gasket—this ensures proper sealing and prevents the gasket from binding during installation.

Hand-tightening represents the most critical aspect of installation. Thread the new Microgard Select Oil Filter on by hand until the gasket contacts the mounting surface, then tighten an additional three-quarters turn by hand. Resist the temptation to use a filter wrench for final tightening—over-tightening can damage the gasket, distort the housing, or make future removal extremely difficult.

After installation, add the appropriate amount of fresh oil and start the engine, allowing it to run for several minutes while monitoring for leaks. Check the oil level after shutdown and top off as necessary. The initial startup allows the new filter to fill completely and establishes proper oil pressure throughout the system.

Market Access and Investment: Finding and Purchasing Your Microgard Select Oil Filter

Acquiring a Microgard Select Oil Filter has become increasingly convenient as the product’s reputation for quality has expanded distribution channels. Understanding where to find authentic Select filters and what to expect in terms of pricing helps ensure you receive genuine protection for your investment.

Automotive parts retailers represent the primary distribution channel for Microgard Select Oil Filters. Major chains like AutoZone, O’Reilly Auto Parts, and Advance Auto Parts typically stock common applications, while many maintain special-order capabilities for less common vehicles. These retailers often provide knowledgeable staff who can help identify the correct filter for your specific application and may offer installation services for customers who prefer professional installation.

Online retailers have emerged as another popular option, offering competitive pricing and convenient home delivery. Platforms like Amazon, RockAuto, and manufacturer websites provide extensive catalogs with detailed compatibility information. The online environment allows for easy price comparison and access to customer reviews, though buyers should verify they’re purchasing from authorized dealers to ensure authenticity.

Dealerships and professional service centers increasingly offer Microgard Select Oil Filters as premium upgrade options. While pricing may be higher than retail channels, dealership installation ensures proper application selection and professional installation, often backed by service warranties. Many customers find the peace of mind worth the additional cost, particularly for high-value vehicles.

Fleet and commercial buyers often benefit from direct relationships with Microgard distributors or the manufacturer itself. Volume purchasing can result in significant cost savings, while direct relationships ensure priority access to new products and technical support. Many distributors offer customized programs that align filter delivery with maintenance schedules, reducing inventory costs and ensuring fresh stock.

Pricing for Microgard Select Oil Filters typically ranges from $8-25 depending on application, with passenger car filters generally falling in the $8-15 range and heavy-duty applications commanding premium prices. While this represents a modest increase over standard filters, the extended service life and superior protection often result in lower overall costs when calculated on a per-mile basis.

Longevity and Economics: Understanding Service Life and Value

The service life of a Microgard Select Oil Filter extends well beyond simple mileage considerations, encompassing a complex interaction of operating conditions, oil quality, and maintenance practices that ultimately determine both protection effectiveness and economic value. Understanding these factors helps maximize both filter performance and return on investment.

Under ideal conditions—regular highway driving, quality synthetic oil, moderate temperatures, and clean fuel—a Microgard Select Oil Filter can provide effective filtration for 12,000-15,000 miles or more. This extended capability stems from the filter’s advanced media design and superior dirt-holding capacity, which maintain filtration efficiency even as contamination levels increase throughout the service interval.

Real-world conditions often present greater challenges that affect service life. Stop-and-go driving generates higher contamination loads due to increased fuel dilution and incomplete combustion. Extreme temperatures stress both oil and filter components, while poor fuel quality can introduce additional contaminants that reduce filter capacity. Even under these challenging conditions, the Microgard Select Oil Filter typically provides 7,500-10,000 miles of effective service, representing significant improvement over standard alternatives.

The economic value proposition of the Microgard Select Oil Filter becomes apparent when analyzing total cost of ownership rather than simple purchase price. While the initial cost may exceed standard filters by $3-8, the extended service life often results in fewer filter changes over time. More importantly, the superior protection can dramatically reduce engine wear, potentially extending engine life by tens of thousands of miles.

Independent analysis has shown that engines protected by Microgard Select Oil Filters maintain better compression, suffer less bearing wear, and require fewer major repairs over their operational lifetime. For a typical passenger vehicle, this enhanced protection can translate to $2,000-5,000 in avoided repair costs over the engine’s life, making the modest premium for Select filters one of the most cost-effective modifications possible.

Fleet operations have documented even more dramatic savings. Commercial vehicles operating with Microgard Select Oil Filters show reduced maintenance costs, fewer unexpected breakdowns, and extended overhaul intervals. These benefits combine to improve fleet availability while reducing per-mile operating costs, making the Select filters virtually mandatory for cost-conscious fleet managers.

Performance Enhancement: Quantifying Engine Benefits

The impact of the Microgard Select Oil Filter on engine performance extends beyond simple contamination removal, creating measurable improvements in power output, fuel economy, and operational smoothness that drivers can actually feel and document. Understanding these performance benefits helps illustrate why filter choice represents one of the most impactful maintenance decisions vehicle owners make.

Power output improvements result primarily from reduced internal friction and better oil pressure maintenance throughout the service interval. Independent dyno testing has documented 2-4% power increases in engines equipped with Microgard Select Oil Filters compared to standard alternatives. While these gains may seem modest, they represent meaningful improvements in real-world performance, particularly during acceleration and hill climbing.

The mechanism behind these power gains involves maintaining optimal oil film thickness on critical bearing surfaces. Standard filters often experience pressure drop as they accumulate contaminants, forcing oil pumps to work harder while potentially compromising lubrication quality. The Microgard Select Oil Filter maintains consistent pressure throughout its service life, ensuring adequate lubrication even under high-demand conditions.

Fuel economy improvements stem from multiple factors related to superior filtration. Cleaner oil maintains its lubricating properties longer, reducing the energy required to overcome internal friction. Additionally, consistent oil pressure ensures optimal variable valve timing operation in modern engines, maintaining peak combustion efficiency throughout the service interval. Real-world testing has documented 2-4% fuel economy improvements with Microgard Select Oil Filters, savings that compound significantly over thousands of miles.

Engine smoothness represents another area where the Microgard Select Oil Filter delivers noticeable benefits. By maintaining cleaner oil longer, the filter helps preserve the precise tolerances that ensure smooth operation. Drivers often report reduced engine noise, smoother idle quality, and improved throttle response after switching to Select filters, particularly as the engine accumulates miles.

Cold-start performance also benefits from the Microgard Select Oil Filter’s superior design. The filter’s optimized flow characteristics ensure rapid oil circulation during startup, when engine wear is typically highest. This rapid circulation helps protect critical components during the crucial first few seconds of operation when oil pressure is building and lubrication is most critical.

Perhaps most importantly for performance enthusiasts, the Microgard Select Oil Filter helps maintain consistent performance throughout extended high-load operation. Whether you’re towing a trailer, driving enthusiastically on winding roads, or participating in track events, the filter’s superior protection ensures your engine maintains optimal lubrication even under demanding conditions.

Material Science: The Technology Behind the Protection

The Microgard Select Oil Filter represents the culmination of advanced material science, incorporating cutting-edge synthetic fibers, precision-engineered housing components, and specialized sealing technologies that work together to create unprecedented filtration performance. Understanding these materials and their properties provides insight into why Select filters deliver superior protection and longevity.

The filtration media represents the heart of the Microgard Select Oil Filter, utilizing a proprietary blend of synthetic and cellulose fibers that creates a three-dimensional filtration matrix. Unlike conventional filters that rely primarily on cellulose (wood pulp) fibers, the Select series incorporates advanced synthetic fibers with precisely controlled diameter and length characteristics. These synthetic components maintain their structure and filtration efficiency even under extreme pressure differentials and temperature variations.

The fiber blend is engineered to create tortuous pathways that maximize particle capture while minimizing pressure drop. Computer modeling helps optimize fiber orientation and density to achieve the ideal balance between filtration efficiency and oil flow characteristics. The result is a media that can capture 99% of particles larger than 20 microns while maintaining flow rates sufficient for modern high-performance engines.

Resin bonding systems used in Microgard Select Oil Filters represent another area of material advancement. Instead of traditional wet-strength additives that can break down over time, Select filters employ advanced synthetic resins that maintain their binding properties throughout extended service intervals. These resins also provide enhanced chemical resistance, preventing degradation from fuel dilution and combustion byproducts that can compromise lesser filters.

The housing construction utilizes high-strength steel with specialized coatings that resist corrosion while maintaining dimensional stability. The steel itself is selected for its ability to maintain thread integrity under high torque loads while resisting deformation under pressure. Advanced coating technologies provide additional protection against galvanic corrosion when the filter is mounted to dissimilar metals.

Sealing technology in the Microgard Select Oil Filter incorporates nitrile rubber compounds specifically formulated for extended oil contact. These gaskets maintain their sealing properties across a wide temperature range while resisting the swelling and degradation that can affect standard rubber seals. The gasket design itself features optimized compression characteristics that ensure reliable sealing without requiring excessive installation torque.

Internal components, including the center tube and end caps, are manufactured to precision tolerances that ensure optimal oil flow distribution. The center tube features carefully engineered perforation patterns that promote even flow across the entire media surface, maximizing filtration efficiency while preventing premature media loading in localized areas.

Quality Assurance: Warranty Protection and Performance Guarantees

The confidence that Microgard places in their Select filter technology is reflected in comprehensive warranty coverage and performance guarantees that provide peace of mind for consumers and demonstrate the manufacturer’s commitment to quality. Understanding these protections helps illustrate the difference between the Microgard Select Oil Filter and lesser alternatives that may lack adequate backing.

Manufacturing warranties cover defects in materials and workmanship for the life of the filter, ensuring that any premature failure due to manufacturing issues will be addressed without cost to the consumer. This coverage includes replacement of the defective filter and compensation for any resulting engine damage, provided the filter was installed and used according to manufacturer specifications.

Performance guarantees represent an even more significant commitment from Microgard. The company guarantees that Microgard Select Oil Filters will provide the specified filtration efficiency and dirt-holding capacity throughout their recommended service interval when used under normal operating conditions. This guarantee is backed by extensive testing and quality control measures that ensure each filter meets strict performance standards.

Quality control processes begin with incoming material inspection, where every component is verified against specifications before entering the manufacturing process. Filtration media undergoes bubble point testing to verify pore size distribution, while housing components are checked for dimensional accuracy and material properties. This initial screening ensures that only quality components enter the assembly process.

Manufacturing process controls include continuous monitoring of critical assembly parameters such as media pleating consistency, end cap sealing pressure, and bypass valve calibration. Statistical process control techniques identify any trends that might affect quality before they result in defective products, ensuring consistent performance across all production runs.

Final inspection protocols subject every Microgard Select Oil Filter to pressure testing, flow verification, and visual inspection before packaging. Random samples from each production lot undergo additional testing including burst pressure testing, filtration efficiency measurement, and accelerated aging tests that simulate extended service conditions.

Third-party testing validation provides additional assurance of Microgard Select Oil Filter performance. Independent laboratories regularly verify that production filters meet published specifications, while ongoing testing programs monitor long-term performance trends. This external validation ensures that published performance claims accurately reflect real-world capabilities.

Customer support services back up the warranty and guarantee programs with technical assistance and problem resolution capabilities. Trained technicians can provide application guidance, troubleshooting assistance, and warranty claim processing to ensure customer satisfaction. This support infrastructure demonstrates Microgard’s commitment to standing behind their products throughout the ownership experience.

Wear Prevention: The Science of Engine Protection

The ability of the Microgard Select Oil Filter to prevent engine wear represents perhaps its most important benefit, directly impacting engine longevity, performance retention, and overall vehicle reliability. Understanding the mechanisms by which superior filtration prevents wear helps illustrate why filter choice is one of the most critical maintenance decisions vehicle owners make.

Abrasive wear represents the primary threat to engine longevity, occurring when hard particles circulate through oil passages and contact critical bearing surfaces. These particles, ranging from metal wear debris to combustion byproducts and environmental contaminants, act like microscopic grinding compound that gradually removes material from precisely machined surfaces. The Microgard Select Oil Filter combats this wear mechanism by capturing particles before they can cause damage.

The filter’s advanced media design creates multiple opportunities to capture particles throughout their journey through the oil system. Large particles are captured immediately upon entering the filter, while progressively smaller particles are trapped as oil penetrates deeper into the media structure. This multi-stage capture prevents particles from circulating repeatedly through the engine, where they could cause cumulative damage over time.

Bearing protection represents a critical area where the Microgard Select Oil Filter excels. Engine bearings maintain oil films measured in microns, making them extremely vulnerable to particle contamination. When particles larger than the oil film thickness pass through bearing surfaces, they cause micro-welding and material transfer that gradually increase bearing clearances and reduce oil pressure. Superior filtration maintains bearing clearances within specification longer, preserving oil pressure and protecting downstream components.

Cylinder wall protection is equally important for maintaining engine performance and preventing oil consumption. Particles that reach the cylinder walls can embed in the relatively soft aluminum or iron, creating scratches that compromise ring sealing and allow oil past the rings. The Microgard Select Oil Filter prevents this contamination from reaching the cylinders, maintaining compression and preventing the oil consumption that often signals internal engine wear.

Hydraulic component protection becomes increasingly important in modern engines with variable valve timing, cylinder deactivation, and turbocharger systems. These components rely on precise oil pressure and clean oil for proper operation, making them vulnerable to contamination that might not affect older, simpler engines. The consistent pressure and superior cleanliness provided by Microgard Select Oil Filters ensure these systems operate as designed throughout their service life.

The cumulative effect of this comprehensive wear prevention extends far beyond simple component longevity. Engines protected by Microgard Select Oil Filters maintain their original performance characteristics longer, suffer fewer unexpected failures, and often achieve double or triple the service life of engines using standard filtration. This protection represents one of the most cost-effective investments possible in vehicle reliability and longevity.

Comparative Analysis: Filtration Efficiency in Context

When evaluating the Microgard Select Oil Filter against competing products, filtration efficiency emerges as the primary differentiator that separates premium filters from standard alternatives. However, understanding filtration efficiency requires looking beyond simple marketing claims to examine standardized test results and real-world performance data that reveal actual capabilities.

Industry-standard testing protocols, including ISO 4548-12 and SAE J1858, provide objective measures of filtration efficiency across various particle sizes. These tests reveal that while standard filters might capture 85-90% of particles larger than 30 microns, the Microgard Select Oil Filter achieves 99% efficiency at 20 microns and maintains significant capture rates down to 10 microns. This superior performance stems from the advanced media design and precision manufacturing that characterizes the Select series.

Beta ratio testing provides another perspective on filtration performance, measuring the ratio of particles upstream versus downstream of the filter. A beta ratio of 100 indicates 99% efficiency, while ratios of 200 or higher indicate efficiency approaching 99.5%. Microgard Select Oil Filters consistently achieve beta ratios exceeding 200 for particles larger than 20 microns, performance levels that place them among the top tier of automotive oil filters.

Dirt-holding capacity comparisons reveal another area where the Microgard Select Oil Filter excels. While standard filters might hold 8-12 grams of contaminants before reaching capacity, Select filters can accommodate 15-20 grams or more while maintaining filtration efficiency. This enhanced capacity translates to longer service life and more consistent protection throughout the service interval.

Flow characteristics represent an often-overlooked aspect of filter performance that significantly impacts engine protection. Some filters achieve high efficiency by restricting flow, potentially compromising engine lubrication under high-demand conditions. The Microgard Select Oil Filter maintains optimal flow rates while achieving superior efficiency, ensuring adequate lubrication even during extended high-RPM operation.

Multi-pass testing, which simulates extended service conditions by repeatedly circulating contaminated oil through the filter, demonstrates the Microgard Select Oil Filter’s ability to maintain performance over time. While some filters show declining efficiency as they accumulate contaminants, Select filters maintain consistent capture rates until they approach their dirt-holding capacity, providing predictable protection throughout their service life.

Comparative analysis of used filters provides real-world validation of laboratory testing. Microgard Select Oil Filters removed from service consistently show more uniform contamination loading and better structural integrity than competing products, confirming that superior laboratory performance translates to enhanced real-world protection.

User Experience: Performance Reviews and Real-World Feedback

The true measure of the Microgard Select Oil Filter’s effectiveness comes from the experiences of real users who have installed these filters and documented their performance over extended periods. These real-world experiences provide insights that laboratory testing alone cannot capture, revealing how the filters perform under actual driving conditions and maintenance practices.

Professional mechanics consistently report positive experiences with Microgard Select Oil Filters, noting their robust construction and consistent performance. Many shops have adopted Select filters as their premium offering, citing reduced callback rates and improved customer satisfaction compared to standard alternatives. Mechanics particularly appreciate the filters’ resistance to damage during installation and removal, reducing the risk of stuck filters or damaged mounting threads.

Fleet managers have documented significant cost savings after switching to Microgard Select Oil Filters. One major delivery company reported a 30% reduction in engine-related maintenance costs after implementing Select filters across their fleet of 200 vehicles. The improved reliability and extended service capability reduced both direct maintenance costs and vehicle downtime, improving overall operational efficiency.

Enthusiast communities have embraced Microgard Select Oil Filters for high-performance applications, with many users reporting improved oil pressure retention and cleaner oil at change intervals. Track day participants note the filters’ ability to maintain protection during extended high-RPM operation, while turbocharged vehicle owners appreciate the consistent flow characteristics that support proper turbocharger lubrication.

Independent oil analysis results provide objective validation of user experiences. Vehicles equipped with Microgard Select Oil Filters consistently show lower particle counts and wear metal concentrations in oil analysis reports, confirming the filters’ superior protection capabilities. These results often translate to extended oil change intervals and reduced wear-related maintenance requirements.

Long-term users frequently report engines that maintain like-new performance characteristics well beyond 100,000 miles. One taxi operator documented an engine reaching 400,000 miles with Microgard Select Oil Filters while maintaining original compression specifications and showing minimal internal wear during inspection. Such examples, while exceptional, demonstrate the potential benefits of superior filtration over extended periods.

Customer satisfaction surveys consistently rate Microgard Select Oil Filters highly for perceived quality, installation ease, and performance benefits. Users particularly appreciate the confidence that comes from knowing their engine receives premium protection, often citing the modest additional cost as insignificant compared to the peace of mind provided.

Diesel Applications: Heavy-Duty Protection for Heavy-Duty Engines

Diesel engines present unique filtration challenges that make the Microgard Select Oil Filter not just beneficial but essential for optimal performance and longevity. The operating characteristics of diesel engines—including higher compression ratios, increased operating pressures, and different combustion byproducts—create contamination loads and filtration demands that standard filters simply cannot address effectively.

Soot loading represents perhaps the greatest challenge in diesel engine filtration. Unlike gasoline engines that produce primarily liquid contaminants, diesel engines generate significant quantities of carbon soot that must be captured and contained by the oil filter. The Microgard Select Oil Filter incorporates specialized media designed to handle these higher soot loads while maintaining oil flow and filtration efficiency.

The three-dimensional structure of the Select filter media provides enhanced soot-holding capacity compared to conventional filters. Instead of forming a surface cake that restricts flow, soot particles are captured throughout the media depth, allowing continued oil circulation even as contamination levels increase. This design prevents the premature bypass valve opening that plagues standard filters in diesel applications.

Acid neutralization becomes critical in diesel engines due to sulfur compounds in fuel that form acids during combustion. These acids can corrode internal components and degrade oil quality if not properly managed. The Microgard Select Oil Filter works in conjunction with diesel oil additive packages to contain acid-forming contaminants while maintaining oil alkalinity throughout extended service intervals.

Fuel dilution presents another challenge specific to diesel applications, particularly in modern engines with regenerative particulate filters. Fuel injected during regeneration cycles can dilute engine oil, reducing its viscosity and compromising its protective properties. The superior flow characteristics of Microgard Select Oil Filters ensure adequate oil circulation even when viscosity is reduced by fuel dilution.

Commercial diesel applications often operate under severe conditions that accelerate contamination generation. Extended idling, heavy load operation, and dusty environments all contribute to increased filter loading. The enhanced dirt-holding capacity of Microgard Select Oil Filters provides extended protection under these challenging conditions, reducing maintenance frequency and improving operational reliability.

Turbocharger protection becomes particularly important in modern diesel engines where turbochargers operate at extreme speeds and temperatures. Clean oil with consistent flow characteristics is essential for proper turbocharger lubrication and cooling. The Microgard Select Oil Filter ensures that turbochargers receive the clean, pressurized oil they require for reliable operation and extended service life.

Application Selection: Choosing the Perfect Filter Match

Selecting the correct Microgard Select Oil Filter for your specific vehicle requires understanding both the technical specifications of your engine and the various filter configurations available. This selection process goes beyond simple part number matching to consider factors like engine design, operating conditions, and performance requirements that influence optimal filter choice.

Engine displacement and oil system design represent primary considerations in filter selection. Larger engines typically require filters with higher flow capacity to ensure adequate circulation, while high-performance engines may need filters optimized for sustained high-pressure operation. The Microgard Select Oil Filter line includes variants specifically engineered for different engine families, ensuring optimal performance regardless of application.

Thread pitch and mounting configuration must match exactly to ensure proper installation and sealing. The Microgard Select Oil Filter catalog includes detailed fitment information that specifies not only thread specifications but also gasket type, housing dimensions, and any special installation considerations. This comprehensive approach prevents fitment issues that could compromise engine protection.

Bypass valve calibration varies among different Microgard Select Oil Filter models to match the pressure characteristics of specific engines. High-performance engines with strong oil pumps may require filters with higher bypass valve settings to ensure maximum filtration, while economy engines with lower-pressure systems need filters calibrated for their operating range.

Climate considerations influence filter selection for vehicles operating in extreme temperatures. Cold climate applications benefit from filters with enhanced flow characteristics at low temperatures, while hot climate operation requires filters with superior thermal stability. The Microgard Select Oil Filter line includes variants optimized for these specific conditions.

Service interval requirements also influence filter choice. Fleet vehicles requiring extended service intervals need filters with maximum dirt-holding capacity, while performance applications requiring frequent oil changes can prioritize filtration efficiency over capacity. Understanding your specific maintenance requirements helps identify the optimal Select filter variant.

Professional consultation can provide valuable guidance in filter selection, particularly for specialized applications or unusual operating conditions. Microgard technical support can provide application-specific recommendations based on detailed vehicle information and operating requirements, ensuring optimal filter selection for any application.

The selection process should also consider future modifications or changes in operating conditions. Vehicles that may be modified for increased performance or different service requirements benefit from filters that provide margin for these potential changes. The superior capabilities of Microgard Select Oil Filters often provide this margin while delivering excellent performance in stock applications.

The Future of Engine Protection

As we look toward an automotive future increasingly defined by efficiency, performance, and environmental consciousness, the Microgard Select Oil Filter represents more than just an advanced replacement part—it embodies a philosophy of proactive protection that can extend engine life, reduce environmental impact, and provide tangible economic benefits that compound over years of ownership.

The investment in a Microgard Select Oil Filter pays dividends far beyond its modest purchase price. Through superior particle capture, extended service life, and comprehensive engine protection, this advanced filtration technology can add tens of thousands of miles to your engine’s operational life while maintaining the performance characteristics that make driving enjoyable.

Whether you’re maintaining a daily commuter, protecting a high-performance vehicle, or managing a commercial fleet, the Microgard Select Oil Filter offers a level of protection that transforms routine maintenance into proactive investment in your vehicle’s future. In a world where quality and reliability matter more than ever, choosing the right filter isn’t just about meeting requirements—it’s about exceeding them in every way that matters.

The science is clear, the benefits are documented, and the choice is yours. Your engine deserves the ultimate protection that only a Microgard Select Oil Filter can provide. Make the choice that your future self will thank you for, and experience the difference that truly advanced filtration technology can make in your vehicle’s performance, reliability, and longevity.