MicroGard Fuel Filter – 33003

- Replacing the fuel filter provides two benefits. First, the fuel filter protects the injectors from debris that cause damage and clogging. Second, a new fuel filter has less restriction, preventing the fuel pump from working too hard.

Protecting Your Investment One Drop at a Time – The Complete Guide to Superior Fuel Filtration

Your vehicle’s engine is a marvel of engineering, with thousands of precision components working in perfect harmony to deliver the power and performance you depend on every day. But like any sophisticated machine, it’s only as good as what goes into it. This is where the often-overlooked hero of automotive maintenance comes into play: the Microgard fuel filter. Far from being just another component in your vehicle’s complex system, this small but mighty device stands as the sentinel guarding your engine’s most vital pathways.

Imagine for a moment that your vehicle’s fuel system is like the circulatory system of a living organism. Just as your blood needs to be clean and free of harmful contaminants to keep your body healthy, your engine needs pure, filtered fuel to maintain optimal performance. The Microgard fuel filter serves as the kidney of this automotive circulatory system, continuously cleaning and purifying the lifeblood that keeps your engine running smoothly.

Understanding the Microgard Fuel Filter: Engineering Excellence in a Compact Package

When we ask “What is a Microgard fuel filter?” we’re really exploring a sophisticated piece of automotive technology that represents decades of engineering refinement. A Microgard fuel filter is a high-performance filtration device designed to remove contaminants, sediments, and impurities from fuel before it reaches your engine’s delicate injection system or carburetor.

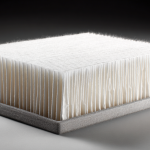

Unlike generic alternatives that might use basic filtration materials, Microgard fuel filters are constructed with advanced synthetic media that can capture particles as small as 10 microns while maintaining optimal fuel flow rates. This isn’t just about removing visible dirt and debris; modern fuel systems operate under tremendous pressure and require fuel that’s free from even microscopic contaminants that could damage precision-machined components.

The engineering behind a Microgard fuel filter reflects a deep understanding of modern automotive requirements. These filters are designed to handle not just traditional gasoline, but also the various fuel blends and additives that have become standard in today’s market. Whether you’re dealing with ethanol-blended fuels, premium gasoline with cleaning agents, or even diesel fuel in commercial applications, a Microgard fuel filter adapts to provide consistent protection.

The Science Behind Superior Filtration: How Microgard Fuel Filters Work

Understanding how a Microgard fuel filter works requires appreciating the complex journey fuel takes from your gas tank to your engine’s combustion chambers. When you start your vehicle, the fuel pump creates pressure that pushes fuel through various lines and components. Before this fuel can reach the engine, it must pass through the Microgard fuel filter, where the real magic happens.

The filtration process begins as fuel enters the filter housing under pressure. The Microgard fuel filter uses a multi-layered approach to contamination removal. The outer layer catches larger particles like rust flakes, dirt, and sediment that might have entered the fuel tank during filling or through normal wear of fuel system components. As fuel moves deeper into the filter media, progressively finer layers capture smaller contaminants, including water droplets that could cause corrosion or combustion problems.

What sets a Microgard fuel filter apart is its engineered pore structure. The filter media is designed with graduated pore sizes that create a tortuous path for contaminants while allowing clean fuel to flow freely. This design maximizes filtration efficiency without creating excessive pressure drop that could strain your fuel pump or reduce engine performance.

The pleated design of most Microgard fuel filters significantly increases the surface area available for filtration, extending the filter’s service life while maintaining consistent performance. As contaminants accumulate on the filter media, the Microgard fuel filter continues to function effectively until it reaches its designed capacity, at which point replacement becomes necessary to maintain optimal protection.

Is a Microgard Fuel Filter Right for Your Vehicle?

The question “Is a Microgard fuel filter good for my vehicle?” touches on one of the most important decisions you can make for your automotive investment. The answer is unequivocally yes, regardless of whether you drive a compact economy car, a powerful sports vehicle, or a heavy-duty truck. The benefits of using a Microgard fuel filter extend far beyond basic contamination removal.

Modern engines, particularly those with direct injection systems, turbochargers, or high-performance configurations, are especially sensitive to fuel quality. The precise tolerances in fuel injectors, the delicate balance required for optimal combustion, and the extreme pressures involved in modern fuel delivery systems all demand the level of protection that only a quality Microgard fuel filter can provide.

Consider the typical fuel injector in a modern vehicle. These components operate with clearances measured in thousandths of an inch and pressures that can exceed 2,000 PSI in some systems. Even microscopic particles that might seem insignificant can cause expensive damage or performance degradation when they interfere with these precision components. A Microgard fuel filter provides the level of filtration necessary to protect these sophisticated systems.

The compatibility of Microgard fuel filters extends across virtually every make and model of vehicle on the road today. From vintage classics to the latest hybrid and electric vehicles with range-extending engines, there’s likely a Microgard fuel filter engineered specifically for your application. This universal compatibility stems from Microgard’s comprehensive approach to product development, which considers the unique requirements of different engine types, fuel systems, and operating conditions.

The Critical Timing: When to Replace Your Microgard Fuel Filter

One of the most frequently asked questions about automotive maintenance revolves around replacement intervals: “How often should I replace a Microgard fuel filter?” The answer depends on several factors, but understanding these variables can help you maintain optimal engine protection while avoiding unnecessary expenses.

For most passenger vehicles under normal operating conditions, a Microgard fuel filter should be replaced every 30,000 to 40,000 miles. However, this general guideline doesn’t account for the wide variety of driving conditions and fuel quality variations that can significantly impact filter life. Vehicles operated in dusty environments, those that frequently use fuel from questionable sources, or cars that sit unused for extended periods may require more frequent Microgard fuel filter replacement.

The quality of fuel available in your area plays a crucial role in determining replacement intervals. Regions with older fuel infrastructure, areas prone to water contamination, or locations where fuel turnover at stations is slow may expose your Microgard fuel filter to higher levels of contaminants. In these situations, reducing the replacement interval to every 20,000 to 25,000 miles can provide additional protection for your engine.

Seasonal considerations also affect Microgard fuel filter replacement timing. Winter fuel blends, which often contain additives to prevent gelling and improve cold-weather performance, can sometimes carry additional contaminants. Similarly, the transition between seasonal fuel blends can introduce temporary quality variations that increase the workload on your Microgard fuel filter.

Professional mechanics often recommend replacing the Microgard fuel filter as part of major service intervals, combining it with other maintenance tasks to maximize efficiency and minimize labor costs. This approach ensures that your fuel filtration system receives attention at appropriate intervals while taking advantage of economies of scale in maintenance scheduling.

The Multifaceted Benefits of Microgard Fuel Filter Technology

The benefits of using a Microgard fuel filter extend far beyond simple contamination removal, creating a cascade of positive effects throughout your vehicle’s operation. These advantages touch every aspect of your driving experience, from immediate performance improvements to long-term cost savings and environmental benefits.

Enhanced engine performance represents one of the most noticeable benefits of a quality Microgard fuel filter. Clean fuel burns more completely and consistently, resulting in smoother idle, improved acceleration response, and more predictable power delivery across the engine’s operating range. Drivers often report that their vehicles feel more responsive and refined after installing a fresh Microgard fuel filter, particularly if the previous filter had become significantly contaminated.

Fuel efficiency improvements constitute another significant advantage of Microgard fuel filter technology. When your engine receives consistently clean fuel, it can operate at its designed efficiency levels without compensating for contamination-related combustion irregularities. This optimization can result in measurable improvements in miles per gallon, especially in vehicles with sophisticated engine management systems that continuously adjust fuel delivery based on operating conditions.

The protective benefits of a Microgard fuel filter extend throughout the fuel system, safeguarding expensive components that would otherwise be vulnerable to contamination damage. Fuel injectors, high-pressure fuel pumps, fuel rail assemblies, and even the engine’s combustion chambers all benefit from the consistent supply of clean fuel that a Microgard fuel filter provides. This protection translates directly into reduced maintenance costs and fewer unexpected repairs over the life of your vehicle.

From an environmental perspective, the benefits of using a Microgard fuel filter align with modern sustainability goals. Cleaner combustion reduces harmful emissions while more efficient fuel utilization decreases overall consumption. These improvements, when multiplied across millions of vehicles, contribute to meaningful reductions in automotive environmental impact.

Professional Installation vs. DIY: Installing Your Microgard Fuel Filter

The installation process for a Microgard fuel filter varies significantly depending on your vehicle’s design, your mechanical expertise, and the tools available to you. Understanding these variables can help you make an informed decision about whether to tackle the installation yourself or seek professional assistance.

For vehicles with easily accessible fuel filters located along the fuel rail or in the engine compartment, Microgard fuel filter installation can be a straightforward DIY project for mechanically inclined owners. These installations typically require basic hand tools, safety equipment, and careful attention to fuel system pressure relief procedures. The process generally involves locating the existing filter, relieving fuel system pressure, disconnecting fuel lines, removing the old filter, and installing the new Microgard fuel filter with proper orientation and secure connections.

However, many modern vehicles locate the fuel filter inside the fuel tank as part of the fuel pump assembly, making Microgard fuel filter replacement a more complex procedure that often requires dropping the fuel tank or removing rear seat assemblies to access the pump module. These installations demand specialized tools, considerable mechanical expertise, and strict adherence to safety protocols for working with fuel systems.

Regardless of whether you choose professional installation or tackle the job yourself, certain safety considerations apply to all Microgard fuel filter replacements. Fuel systems operate under pressure even when the engine is off, and improper handling can result in fuel spillage, fire hazards, or personal injury. Professional installers have the experience, tools, and safety equipment necessary to handle these risks effectively.

Professional installation also provides the advantage of system inspection during the replacement process. Experienced technicians can identify potential issues with fuel lines, connections, or other system components that might not be apparent to DIY installers. This comprehensive approach ensures that your Microgard fuel filter installation contributes to overall fuel system reliability rather than simply addressing the immediate filtration need.

Sourcing Your Microgard Fuel Filter: Navigation the Marketplace

Finding the right Microgard fuel filter for your vehicle requires understanding the various distribution channels available and the factors that influence pricing and availability. The marketplace for automotive filters has evolved significantly in recent years, offering consumers multiple options for acquiring quality filtration products.

Traditional automotive parts stores remain a primary source for Microgard fuel filters, offering the advantage of knowledgeable staff who can assist with part identification and provide installation advice. These retailers typically maintain comprehensive databases that can match Microgard fuel filters to specific vehicle applications, reducing the risk of purchasing incorrect components. The immediate availability of parts at local stores also eliminates shipping delays when you need a Microgard fuel filter replacement quickly.

Online retailers have revolutionized Microgard fuel filter purchasing by offering extensive inventories, competitive pricing, and convenient home delivery. The digital marketplace allows easy comparison shopping and access to customer reviews that can inform purchasing decisions. However, online purchasing requires careful attention to part numbers and vehicle compatibility to ensure you receive the correct Microgard fuel filter for your application.

Professional service facilities represent another avenue for Microgard fuel filter acquisition, often bundling parts with installation services for convenience and warranty protection. While this approach may carry higher total costs, it provides the peace of mind that comes with professional installation and the ability to address any complications that might arise during the replacement process.

Wholesale distributors and fleet supply companies offer Microgard fuel filters in larger quantities, making them attractive options for fleet operators, professional mechanics, or enthusiasts who maintain multiple vehicles. These sources often provide significant cost savings for bulk purchases while ensuring consistent availability of quality filtration products.

Universal Compatibility: Microgard Fuel Filters Across Vehicle Types

The versatility of Microgard fuel filter products extends across an impressive range of vehicle types, reflecting the company’s comprehensive approach to automotive filtration needs. This broad compatibility ensures that virtually every driver can benefit from the superior protection and performance that Microgard fuel filters provide.

Passenger cars represent the largest segment of Microgard fuel filter applications, encompassing everything from compact economy vehicles to luxury sedans and high-performance sports cars. Each category presents unique filtration challenges that Microgard fuel filters address through specialized designs and materials. Economy vehicles benefit from cost-effective filtration that provides reliable protection without premium pricing, while luxury and performance vehicles receive filters engineered to support their sophisticated fuel systems and demanding operating conditions.

Light trucks and SUVs have become increasingly popular in recent years, and Microgard fuel filters have evolved to meet the specific needs of these vehicles. The larger fuel tanks, higher fuel consumption, and varied operating conditions typical of truck and SUV applications require filters with enhanced capacity and durability. Microgard fuel filters designed for these applications often feature extended service intervals and robust construction to handle the demands of towing, off-road driving, and heavy-duty use.

Commercial vehicles present some of the most challenging filtration requirements in the automotive world. Fleet vehicles, delivery trucks, and commercial vans operate under conditions that would quickly overwhelm inferior filters. Microgard fuel filters for commercial applications are engineered with enhanced capacity, superior filtration efficiency, and extended service life to minimize downtime and maintenance costs for fleet operators.

Diesel vehicles require specialized filtration solutions that address the unique characteristics of diesel fuel and diesel engine operation. Microgard fuel filters for diesel applications are designed to handle the higher viscosity of diesel fuel, remove water that can cause injector damage, and filter the fine particles that diesel combustion systems are particularly sensitive to. These filters often incorporate water separation capabilities and may include features specifically designed for the high-pressure common rail injection systems used in modern diesel engines.

Specialty applications, including motorcycles, marine engines, and recreational vehicles, also benefit from Microgard fuel filter technology. These applications often present unique packaging constraints or environmental challenges that require customized filtration solutions. The comprehensive Microgard fuel filter product line includes options designed specifically for these specialized needs.

Recognizing the Signs: When Your Microgard Fuel Filter Needs Attention

Understanding how to identify when your Microgard fuel filter needs replacement empowers you to maintain optimal vehicle performance while avoiding the costly consequences of filtration failure. The symptoms of a failing fuel filter can be subtle initially but become increasingly apparent as contamination levels rise and flow restriction increases.

Engine performance degradation often provides the first indication that your Microgard fuel filter is approaching the end of its service life. You might notice that your vehicle lacks the power it once had, particularly during acceleration or when climbing hills. This power loss occurs because a restricted Microgard fuel filter cannot supply the volume of fuel your engine needs under high-demand conditions, forcing the engine management system to reduce power output to protect against lean combustion conditions.

Fuel efficiency changes can also signal Microgard fuel filter problems. A contaminated filter forces your fuel pump to work harder to maintain adequate fuel pressure, while combustion irregularities caused by inconsistent fuel flow can reduce overall efficiency. If you notice that your vehicle’s fuel economy has decreased without corresponding changes in driving habits or conditions, your Microgard fuel filter may be contributing to the problem.

Starting difficulties, particularly when the fuel tank is nearly empty, often indicate advanced Microgard fuel filter contamination. As the filter becomes more restrictive, the fuel pump struggles to maintain adequate pressure, especially when fuel levels are low and the pump must work harder to draw fuel from the tank. This condition typically manifests as extended cranking times or rough running immediately after startup.

Engine hesitation or stumbling during acceleration can result from momentary fuel starvation caused by a restricted Microgard fuel filter. When you demand sudden acceleration, your engine needs an immediate increase in fuel flow that a contaminated filter cannot provide. This results in a brief lean condition that causes the engine to hesitate or stumble until fuel flow catches up with demand.

In severe cases, a completely blocked Microgard fuel filter can cause engine stalling or prevent starting altogether. While this extreme condition is relatively rare with quality filters and regular maintenance, it represents the ultimate consequence of neglecting fuel filtration needs.

Comparative Analysis: Microgard vs. The Competition

When evaluating fuel filtration options, understanding what sets Microgard fuel filters apart from competitive products helps inform purchasing decisions and ensures you receive the best possible protection for your investment. The differences between Microgard fuel filters and alternatives extend beyond simple price comparisons to encompass fundamental design philosophy, material quality, and performance characteristics.

Filter media quality represents one of the most significant differentiators in the fuel filter marketplace. Microgard fuel filters utilize advanced synthetic media that provides superior particle retention while maintaining optimal flow characteristics throughout the filter’s service life. Many competitive products rely on paper-based media that may offer adequate initial performance but deteriorate more rapidly under real-world conditions. The synthetic media used in Microgard fuel filters resists degradation from fuel additives, temperature extremes, and moisture exposure that can compromise inferior materials.

Manufacturing precision plays a crucial role in fuel filter performance and reliability. Microgard fuel filters are produced using advanced manufacturing techniques that ensure consistent quality and dimensional accuracy. This precision is particularly important for fuel filters, where proper sealing and flow characteristics are essential for optimal performance. Lower-cost alternatives may exhibit variations in construction quality that can lead to bypass issues, seal failures, or premature restriction.

Engineering support and application expertise distinguish Microgard fuel filters from generic alternatives. The development of each Microgard fuel filter involves extensive research into the specific requirements of target applications, including fuel system pressures, contamination challenges, and service interval expectations. This application-specific engineering ensures that each Microgard fuel filter provides optimal performance for its intended use rather than relying on one-size-fits-all solutions.

Testing and validation procedures for Microgard fuel filters exceed industry standards, providing confidence in long-term performance and reliability. Competitive products may meet basic certification requirements but lack the comprehensive testing protocols that ensure consistent performance under challenging conditions. This additional validation effort contributes to the superior reliability and longevity that Microgard fuel filters are known for.

The Efficiency Connection: How Microgard Fuel Filters Enhance Fuel Economy

The relationship between fuel filtration and fuel efficiency might not be immediately obvious, but the connection is both real and measurable. A quality Microgard fuel filter contributes to improved fuel economy through several mechanisms that optimize combustion efficiency and reduce parasitic losses in the fuel system.

Clean fuel burns more completely and consistently than contaminated fuel, resulting in more efficient energy extraction from each drop of gasoline or diesel. When your Microgard fuel filter removes particles, water, and other contaminants, it enables your engine to achieve its designed combustion efficiency. This optimization is particularly important in modern engines with sophisticated fuel injection systems that rely on precise fuel metering and spray patterns to achieve optimal performance.

Reduced fuel pump workload represents another pathway through which a Microgard fuel filter can improve fuel efficiency. A clean, unrestricted filter allows your fuel pump to maintain adequate system pressure without excessive effort, reducing the electrical load on your vehicle’s charging system. While this effect might seem minimal, the cumulative impact over thousands of miles of driving can result in measurable efficiency improvements.

Engine management system optimization depends heavily on consistent fuel delivery, which a quality Microgard fuel filter helps ensure. Modern engine control systems continuously adjust fuel delivery, ignition timing, and other parameters based on sensor feedback. When fuel contamination causes irregular combustion or inconsistent fuel pressure, these systems must compensate with adjustments that often reduce overall efficiency. A Microgard fuel filter helps maintain the stable operating conditions that allow engine management systems to optimize for maximum efficiency.

Injector protection provided by Microgard fuel filters preserves the precise spray patterns and fuel metering characteristics that modern engines depend on for efficient operation. Contaminated fuel can cause injector deposits or partial blockages that alter spray patterns and reduce fuel atomization quality. These changes force the engine management system to increase fuel delivery to maintain target power output, directly reducing fuel efficiency.

Engine Protection: The Shield Your Investment Deserves

The protective benefits of a Microgard fuel filter extend throughout your engine, safeguarding components that represent thousands of dollars in replacement costs while ensuring reliable operation over your vehicle’s entire service life. Understanding these protective mechanisms helps illustrate why quality fuel filtration represents one of the most cost-effective maintenance investments you can make.

Fuel injection system protection stands as perhaps the most critical function of a Microgard fuel filter in modern vehicles. Today’s fuel injectors operate with extremely tight tolerances and high pressures that make them vulnerable to even microscopic contamination. Particles that pass through inferior filters can cause injector wear, altered spray patterns, or complete blockage. The precision filtration provided by a Microgard fuel filter ensures that only clean fuel reaches these expensive components.

Fuel pump protection represents another significant benefit of quality filtration. Modern electric fuel pumps are designed for long service life when supplied with clean fuel, but contamination can cause premature wear of pump components, leading to reduced pressure capability or complete failure. A Microgard fuel filter removes abrasive particles before they can reach the pump, extending its service life and maintaining consistent fuel system pressure.

High-pressure fuel rail protection is particularly important in direct injection engines, where fuel pressures can exceed 2,000 PSI. The precision-machined components in these systems are extremely sensitive to contamination, and replacement costs can be substantial. A Microgard fuel filter provides the level of filtration necessary to protect these sophisticated systems from contamination damage.

Combustion chamber protection might seem indirect, but contaminated fuel can leave deposits on valves, pistons, and combustion chamber surfaces that reduce engine efficiency and potentially cause long-term damage. The clean fuel provided by a Microgard fuel filter minimizes deposit formation and helps maintain optimal combustion chamber conditions.

Investment Analysis: Understanding Microgard Fuel Filter Costs

When evaluating the cost of a Microgard fuel filter, it’s essential to consider the total cost of ownership rather than simply the initial purchase price. This comprehensive approach reveals that quality filtration represents one of the most cost-effective maintenance investments available to vehicle owners.

Initial Microgard fuel filter costs vary depending on your vehicle’s application and the specific filter design required. Basic filters for economy vehicles typically cost between $15 and $30, while specialized filters for high-performance or diesel applications may range from $25 to $75. When compared to the cost of fuel system repairs or engine damage that could result from inadequate filtration, even premium Microgard fuel filters represent exceptional value.

Installation costs depend largely on your vehicle’s design and whether you choose professional installation or tackle the job yourself. Simple filter replacements might add $50 to $100 in labor costs, while more complex installations requiring fuel tank access could cost $200 to $400 in professional labor. However, many vehicle owners choose to combine Microgard fuel filter replacement with other scheduled maintenance to minimize labor costs.

The long-term cost benefits of using a Microgard fuel filter become apparent when you consider the protection it provides for expensive fuel system components. A single fuel injector replacement can cost $200 to $500, while a complete set of injectors for a V6 or V8 engine can exceed $2,000. High-pressure fuel pump replacement costs often range from $800 to $1,500, depending on the vehicle. When viewed in this context, the cost of regular Microgard fuel filter replacement becomes insignificant compared to the potential repair costs it prevents.

Fuel efficiency benefits provide ongoing cost savings that can offset Microgard fuel filter costs over time. Even a modest 2-3% improvement in fuel economy can save $100 to $200 annually for average drivers, making the filter replacement essentially self-funding while providing valuable engine protection.

Longevity and Lifecycle: Understanding Microgard Fuel Filter Lifespan

The lifespan of a Microgard fuel filter depends on numerous factors that interact in complex ways to determine when replacement becomes necessary. Understanding these variables helps vehicle owners optimize their maintenance schedules while ensuring adequate protection for their fuel systems.

Filter design and capacity play fundamental roles in determining Microgard fuel filter lifespan. Larger filters with more filter media can capture more contaminants before becoming restrictive, extending their service life. However, even the most robust Microgard fuel filter will eventually reach its capacity limit and require replacement to maintain optimal fuel system protection.

Fuel quality represents one of the most significant variables affecting Microgard fuel filter lifespan. High-quality fuel from reputable suppliers with modern filtration and handling systems places minimal burden on your filter, potentially extending its service life beyond standard recommendations. Conversely, poor-quality fuel or fuel from questionable sources can quickly overwhelm even the best Microgard fuel filter, necessitating more frequent replacement.

Driving conditions significantly impact Microgard fuel filter longevity. Vehicles operated primarily on highways under steady-state conditions typically experience longer filter life than those subjected to frequent stop-and-go driving, extreme temperatures, or dusty environments. The fuel consumption patterns associated with different driving styles also affect how quickly contaminants accumulate in the filter.

Vehicle age and fuel system condition influence Microgard fuel filter lifespan through their impact on contamination generation. Older vehicles with aging fuel tanks, lines, and pumps may generate more internal contamination that places additional burden on the filter. Regular fuel system maintenance can help minimize these effects and extend Microgard fuel filter service life.

Diesel Applications: Specialized Filtration for Commercial Power

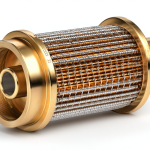

Diesel engines present unique filtration challenges that require specialized solutions, and Microgard fuel filters designed for diesel applications incorporate advanced features to address these specific needs. Understanding these requirements helps diesel vehicle owners appreciate the importance of using appropriate filtration products.

Water separation capability represents one of the most critical features of diesel Microgard fuel filters. Diesel fuel is hygroscopic, meaning it readily absorbs water from the atmosphere, and this water can cause serious damage to high-pressure injection systems. Diesel Microgard fuel filters often incorporate water separation elements that remove both free water and emulsified water from the fuel stream, protecting expensive injection components from corrosion and wear.

Particle filtration requirements for diesel engines are typically more stringent than those for gasoline engines due to the extremely high pressures involved in modern common rail injection systems. Diesel Microgard fuel filters are designed to remove particles down to 2-5 microns, providing the level of cleanliness necessary to protect precision injection components that operate at pressures exceeding 30,000 PSI.

Fuel viscosity considerations affect diesel Microgard fuel filter design, as diesel fuel’s higher viscosity compared to gasoline can create additional flow resistance. Diesel filters must balance filtration efficiency with flow capacity to ensure adequate fuel delivery under all operating conditions, from cold startup to high-power operation.

Cold weather performance becomes particularly important for diesel Microgard fuel filters, as diesel fuel can gel or become cloudy at low temperatures. Specialized diesel filters may incorporate heating elements or use materials that maintain flow characteristics even when fuel temperature drops below normal operating ranges.

Ethanol Compatibility: Modern Fuels, Modern Solutions

The widespread adoption of ethanol-blended fuels has introduced new challenges for fuel filtration systems, and Microgard fuel filters have evolved to address these modern fuel compositions while maintaining superior protection for vehicle fuel systems.

Ethanol’s chemical properties differ significantly from those of pure gasoline, creating unique filtration challenges that Microgard fuel filters are specifically designed to handle. Ethanol is hygroscopic, meaning it readily absorbs water from the atmosphere, and it can also act as a solvent that dissolves certain materials commonly found in older fuel systems. Modern Microgard fuel filters use materials that resist ethanol-related degradation while effectively managing the water content that ethanol fuels can carry.

Corrosion protection becomes particularly important with ethanol-blended fuels, as the alcohol content can accelerate corrosion of certain metals commonly found in fuel systems. Microgard fuel filters designed for ethanol compatibility incorporate corrosion-resistant materials and may include additives that help protect downstream fuel system components from ethanol-related corrosion.

Filter media compatibility with ethanol requires careful material selection to ensure long-term stability and consistent performance. Some filter materials that work well with pure gasoline may degrade when exposed to ethanol blends, leading to filter failure or contamination of the fuel stream. Microgard fuel filters use synthetic media specifically chosen for compatibility with modern fuel blends, ensuring reliable performance regardless of ethanol content.

Phase separation management represents another challenge that Microgard fuel filters help address in ethanol-blended fuels. Under certain conditions, ethanol and gasoline can separate, creating distinct phases that can cause fuel system problems. Quality filtration helps maintain fuel homogeneity and can remove water that might contribute to phase separation.

Precision Selection: Choosing the Right Microgard Fuel Filter

Selecting the correct Microgard fuel filter for your specific vehicle requires understanding several key factors that ensure optimal compatibility and performance. This selection process goes beyond simple part number matching to encompass considerations of fuel system design, operating conditions, and performance expectations.

Vehicle identification represents the starting point for Microgard fuel filter selection, requiring accurate information about your vehicle’s year, make, model, engine size, and fuel system configuration. Modern vehicles often use multiple fuel filter configurations within the same model line, making precise identification crucial for obtaining the correct Microgard fuel filter. Engine codes, VIN numbers, and fuel system specifications can help ensure accurate part identification.

Fuel system pressure ratings must match between your vehicle’s system and the Microgard fuel filter you select. Modern fuel systems operate at pressures ranging from 40 PSI in basic port injection systems to over 2,000 PSI in direct injection applications. Using a filter not rated for your system’s pressure can result in filter failure or inadequate filtration performance.

Flow rate requirements depend on your engine’s fuel consumption characteristics and must be considered when selecting a Microgard fuel filter. High-performance engines or forced-induction applications may require filters with enhanced flow capacity to prevent fuel starvation under high-demand conditions. The Microgard fuel filter product line includes options specifically designed for these demanding applications.

Installation space constraints can limit filter options in some vehicles, particularly those with compact engine compartments or integrated fuel pump assemblies. Understanding your vehicle’s packaging constraints helps ensure that the Microgard fuel filter you select will fit properly and function as intended.

Service interval expectations should align with your maintenance preferences and driving conditions. Some Microgard fuel filters are designed for extended service intervals, while others prioritize maximum filtration efficiency at the cost of more frequent replacement. Matching filter characteristics to your specific needs ensures optimal value and protection.

The Consequences of Neglect: What Happens When Filters Fail

Understanding the potential consequences of operating with a clogged or failed Microgard fuel filter helps illustrate why regular maintenance represents such a critical investment in your vehicle’s long-term health and reliability. These consequences range from minor performance degradation to catastrophic engine damage that can cost thousands of dollars to repair.

Fuel starvation represents the most immediate consequence of a severely restricted Microgard fuel filter. As contamination accumulates and flow restriction increases, your engine may not receive adequate fuel under high-demand conditions. This situation can cause power loss, hesitation, or even stalling, potentially creating dangerous situations if they occur while driving.

Fuel pump damage often results from prolonged operation with a clogged Microgard fuel filter. When the filter becomes restrictive, your fuel pump must work harder to maintain system pressure, leading to increased operating temperatures and accelerated wear. Modern electric fuel pumps are designed for specific operating pressures and flow rates, and forcing them to operate outside these parameters can cause premature failure.

Fuel injection system contamination becomes inevitable when a Microgard fuel filter reaches its capacity limit and begins allowing contaminants to bypass the filter media. Modern fuel injectors operate with extremely tight tolerances, and even microscopic particles can cause wear, altered spray patterns, or complete blockage. Cleaning or replacing contaminated injectors can cost hundreds or thousands of dollars, depending on your vehicle’s configuration.

Engine management system adaptation to poor fuel quality can mask the symptoms of filter problems while causing long-term efficiency losses. Modern engine control systems continuously adjust parameters to maintain smooth operation, but these adaptations often come at the cost of reduced fuel economy and increased emissions. Over time, these adaptations can become permanent, requiring professional reprogramming to restore optimal performance.

Catalyst damage represents a hidden consequence of poor fuel filtration that may not become apparent until emissions testing or comprehensive diagnosis. Contaminated fuel can lead to incomplete combustion and the production of deposits that can damage expensive catalytic converters. Catalyst replacement costs often exceed $1,000 and may require additional repairs to address underlying fuel system problems.

Warranty Protection and Peace of Mind

Microgard fuel filters typically come with comprehensive warranty protection that reflects the manufacturer’s confidence in their products’ quality and reliability. Understanding these warranty provisions helps vehicle owners make informed purchasing decisions while providing peace of mind about their filtration investment.

Manufacturing defect coverage protects against premature filter failure due to materials or construction issues. This coverage typically extends for the filter’s entire recommended service life, ensuring that you won’t be left paying for replacement if a Microgard fuel filter fails to meet its design specifications. However, warranty coverage typically requires proper installation and operation within the filter’s specified parameters.

Performance guarantee provisions ensure that your Microgard fuel filter will provide the filtration efficiency and flow characteristics specified in its technical documentation. This guarantee protects against filters that fail to meet published specifications while providing recourse if performance falls short of expectations.

Installation support may be included with some Microgard fuel filter products, providing access to technical assistance if questions arise during the replacement process. This support can be particularly valuable for DIY installers who encounter unexpected complications or need clarification about proper installation procedures.

Compatibility assurance helps protect against purchasing the wrong Microgard fuel filter for your application, provided that accurate vehicle information was used in the selection process. This protection helps ensure that you receive a filter that will function properly in your specific fuel system configuration.

Material Innovation: The Science Behind Superior Filtration

The materials used in Microgard fuel filter construction represent decades of research and development focused on optimizing filtration performance while ensuring long-term reliability under challenging operating conditions. Understanding these material innovations helps explain why Microgard fuel filters consistently outperform competitive products.

Synthetic filter media used in Microgard fuel filters offers several advantages over traditional paper-based alternatives. These advanced materials resist degradation from fuel additives, temperature extremes, and moisture exposure while maintaining consistent pore structure throughout the filter’s service life. The uniform pore distribution in synthetic media provides more predictable filtration characteristics and longer service life compared to less sophisticated alternatives.

Housing materials must withstand fuel system pressures while resisting corrosion from fuel and environmental exposure. Microgard fuel filters typically use high-strength steel or aluminum alloy housings with specialized coatings that provide long-term corrosion resistance. These materials ensure that the filter housing will maintain its integrity throughout the filter’s service life without contributing contamination to the fuel stream.

Sealing technology plays a crucial role in Microgard fuel filter performance, as even minor leaks can compromise filtration effectiveness while creating safety hazards. Advanced elastomer compounds used in Microgard fuel filters resist swelling and degradation from fuel exposure while maintaining effective sealing across a wide temperature range.

Adhesive and assembly materials used in Microgard fuel filter construction must withstand fuel exposure without contributing contamination or failing under system pressures. These specialized materials undergo extensive testing to ensure compatibility with modern fuel blends while providing reliable long-term performance.

Conclusion: Your Engine’s Future Depends on Today’s Choices

As we reach the end of our comprehensive exploration of Microgard fuel filter technology and applications, it’s clear that this seemingly simple component plays a crucial role in your vehicle’s health, performance, and longevity. The choice to use a quality Microgard fuel filter represents far more than a routine maintenance decision; it’s an investment in your vehicle’s future and a commitment to optimal performance.

The automotive world continues to evolve at a rapid pace, with engines becoming more sophisticated, fuel systems operating at higher pressures, and emissions requirements becoming increasingly stringent. In this environment, the importance of quality fuel filtration cannot be overstated. A Microgard fuel filter provides the foundation for optimal fuel system operation, protecting expensive components while enabling your engine to deliver the performance and efficiency it was designed to provide.

The comprehensive benefits of Microgard fuel filter technology extend throughout your ownership experience, from the immediate satisfaction of smooth engine operation to the long-term peace of mind that comes from knowing your investment is protected. Whether you’re driving a compact economy car, a luxury sedan, a powerful truck, or a commercial vehicle, there’s a Microgard fuel filter engineered specifically to meet your needs.

The relatively modest cost of a Microgard fuel filter pales in comparison to the protection it provides and the potential repair costs it prevents. When you consider that a single fuel system repair can cost more than several years’ worth of filter replacements, the value proposition becomes clear. Quality filtration isn’t an expense; it’s an investment that pays dividends throughout your vehicle’s service life.

As you move forward with your vehicle maintenance planning, remember that the Microgard fuel filter represents one of the most cost-effective ways to protect your automotive investment while ensuring optimal performance. Don’t wait for symptoms to appear or problems to develop. Proactive maintenance with quality Microgard fuel filters keeps your engine running smoothly while preventing the costly consequences of fuel system contamination.

Your engine deserves the best protection available, and Microgard fuel filters deliver that protection with proven reliability, superior performance, and comprehensive compatibility across virtually every vehicle application. Make the choice that automotive professionals recommend, and give your engine the gift of clean fuel with a quality Microgard fuel filter. Your vehicle will reward you with years of reliable, efficient operation that makes every mile a pleasure.